Gas regulators

A gas regulator, also referred to as a pressure regulator or gas governor, is a precision device designed to control and stabilize the flow of gas from a high-pressure source to a lower, controlled pressure suitable for specific applications. Its primary function is to reduce and maintain gas pressure at a safe, consistent level, ensuring the reliable and efficient operation of downstream systems and equipment. Gas regulators are essential components in a wide range of industries, including manufacturing, medical, laboratory, and energy sectors.

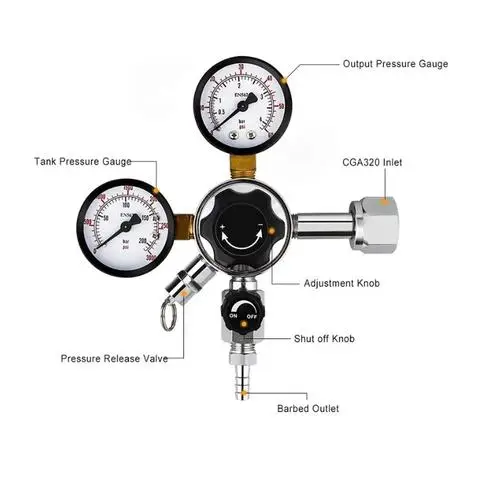

Key Features of Gas Regulators:

- Pressure Control: Accurately reduces high inlet pressure to a stable, lower outlet pressure.

- Safety Assurance: Prevents over-pressurization, protecting equipment and personnel.

- Adjustable Settings: Allows fine-tuning of output pressure based on application needs.

- Pressure Gauges: Equipped with inlet and outlet gauges for real-time pressure monitoring.

- Durable Construction: Made from high-quality materials like brass or stainless steel for long-lasting performance.

What it does:

Reduces Pressure:

Gas regulators decrease the high pressure from sources like gas cylinders, pipelines, or tanks to a lower, more consistent pressure.

Maintains Output Pressure:

They ensure a stable output pressure, even when the incoming pressure fluctuates, which is crucial for consistent performance and safety.

Controls Flow:

They regulate the flow of gas to match the demand of the application.

Safety Mechanism:

Gas regulators often incorporate safety features like relief valves to prevent over-pressurization and potential hazards.

How it works:

Inlet and Outlet Ports:

Gas regulators have an inlet port for the high-pressure gas and an outlet port for the regulated, lower-pressure gas.

Diaphragm:

A flexible diaphragm is a key component. It moves in response to pressure changes, controlling the flow of gas through an orifice.

Spring:

A spring exerts force on the diaphragm, and an adjusting screw allows users to set the desired output pressure.

Single vs. Dual Stage:

Regulators can be single-stage (reducing pressure in one step) or dual-stage (reducing pressure in two stages).

Common Applications:

Industrial:

Controlling gas flow in manufacturing processes, welding, and various industrial applications.

Commercial:

Regulating gas for heating, cooking, and other commercial uses.

Residential:

Providing a safe and controlled gas supply for home appliances like stoves, furnaces, and water heaters.

Medical:

Delivering precise gas flow for medical equipment like ventilators and oxygen delivery systems.

Other:

Used in laboratories, outdoor cooking equipment, and many other applications where gas pressure needs to be controlled.